Our Services

-

27 Years Experience

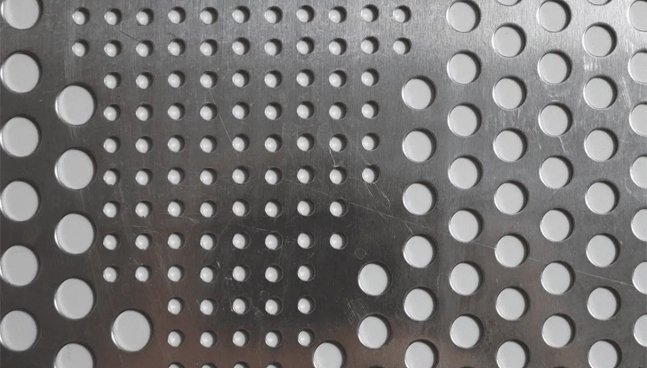

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

MS Perforated Sheets

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi 110091

The Power of MS Perforated Sheets in Industrial Applications

MS Perforated Sheets, often referred to as Mild Steel Perforated Sheets, are a versatile and widely used material in various industries due to their exceptional properties and diverse applications. These sheets, made from high-quality mild steel, undergo a perforation process that creates uniform holes or patterns, offering numerous advantages across multiple sectors.

MS Perforated Sheets

Mild Steel Perforated Sheets are manufactured using high-grade mild steel, known for its durability, strength, and corrosion resistance. The process involves punching holes of various shapes and sizes onto the sheets while maintaining uniformity. The pattern and density of perforations can be customized to meet specific requirements, making these sheets highly adaptable to different applications.

Versatility in Industrial Applications

One of the prominent applications of MS Perforated Sheets lies in architectural design and construction. These sheets are extensively utilized in facades, ceilings, walls, and decorative elements owing to their aesthetic appeal, strength, and durability. The perforated patterns allow for unique designs, lighting effects, and ventilation, adding both functionality and visual interest to structures.

Filtration and Screening

In industries such as agriculture, food processing, and mining, MS Perforated Sheets serve as efficient filters and screens. These sheets' perforations allow for precise filtration of liquids, gases, and solids, making them invaluable in separating materials of varying sizes. The durability of mild steel ensures longevity, making them a cost-effective solution for filtration needs.

Automotive and Aerospace

The automotive and aerospace sectors benefit significantly from the use of MS Perforated Sheets. These sheets find applications in manufacturing components, such as grilles, panels, air vents, and speaker covers. Their lightweight nature, combined with strength and durability, makes them an ideal choice for these industries, contributing to enhanced performance and aesthetics.

Industrial Machinery and Equipment

MS Perforated Sheets play a crucial role in industrial machinery and equipment due to their exceptional strength and versatility. They are utilized in manufacturing conveyor belts, screens, enclosures, and filters. The ability to withstand heavy loads and harsh conditions while facilitating airflow and structural support makes them indispensable in this sector.Advantages of MS Perforated Sheets

The use of high-quality mild steel ensures that these sheets exhibit superior strength and durability, capable of withstanding harsh environmental conditions, corrosion, and mechanical stress. This longevity translates to cost-effectiveness and reliability across various applications.

Customization and Adaptability

The perforation process offers immense flexibility in customization, allowing for tailored patterns, shapes, and sizes as per specific project requirements. This adaptability makes MS Perforated Sheets suitable for a wide array of applications, catering to diverse industry needs.

Improved Aesthetics and Functionality

Beyond their functional advantages, MS Perforated Sheets contribute to enhanced aesthetics in architectural designs and industrial applications. The perforated patterns not only add visual appeal but also serve functional purposes such as ventilation, light diffusion, and sound absorption.

Improved Aesthetics and Functionality

Beyond their functional advantages, MS Perforated Sheets contribute to enhanced aesthetics in architectural designs and industrial applications. The perforated patterns not only add visual appeal but also serve functional purposes such as ventilation, light diffusion, and sound absorption.

MS Perforated Sheets stand as a testament to innovation and versatility in the industrial landscape. Their robustness, adaptability, and multifaceted applications make them an indispensable material across numerous industries, from architecture and filtration to automotive and machinery manufacturing. As technology evolves, these sheets continue to play a pivotal role in advancing efficiency, functionality, and design in various sectors.