Our Services

-

27 Years Experience

We’re Committed to Perforated Metal Sheets Excellence

Weave Tech Engineers is a leading company specializing in providing innovative engineering solutions across various industries. Established with a commitment to excellence, Weave Tech Engineers has built a reputation for delivering high-quality products and services tailored to meet the unique needs of its clients.

Learn More

Perforated Metal Sheets

Metal Sheets- Experience:27 Years

- E-mail:inquiry@weavetechengineers.com

- Phone:098104 06366

- Location:

Mayur Vihar Phase-1

New Delhi, 110091

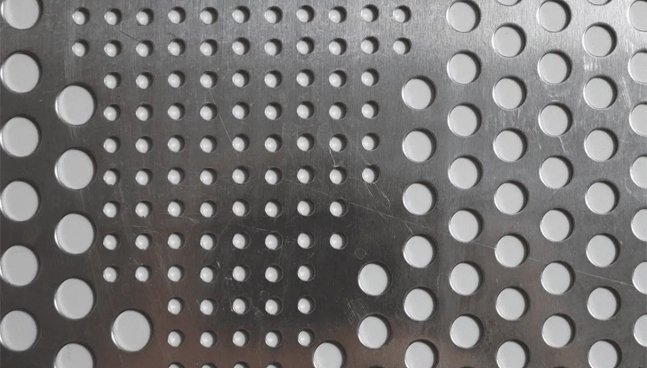

Perforated Metal Sheets: The Ultimate Guide to Applications, Benefits, and Customization

Perforated metal sheets are versatile materials that find application in various industries and settings due to their unique characteristics and adaptability. These sheets, typically made of steel, aluminum, or stainless steel, undergo a process where precise patterns of holes or perforations are strategically punched or stamped into the material.

Architectural and Design Applications

In the realm of architecture and design, perforated metal sheets serve multifaceted purposes. They are used as decorative elements, allowing for creative designs and patterns in facades, sunshades, room dividers, and interior decorations. The perforations not only offer aesthetic appeal but also regulate light, air, and sound, making them ideal for creating functional and visually appealing spaces.

Industrial and Engineering Applications

In industrial settings, perforated metal sheets play crucial roles due to their durability, strength, and versatility. These sheets are used in machinery, filtration systems, noise control panels, and ventilation systems. Their ability to control airflow and filtration makes them indispensable in industries requiring precise airflow or material separation.

Agricultural and Environmental Applications

In the agricultural sector, perforated metal sheets are utilized in farming equipment, grain drying systems, and animal enclosures. They aid in ventilation, separation, and protection while enduring harsh environmental conditions.

Benefits of Perforated Metal Sheets

One of the primary advantages of perforated metal sheets is their inherent strength and durability. The materials used, combined with the precision of perforations, result in a robust product capable of withstanding heavy loads, extreme temperatures, and harsh environments.

Improved Functionality

The perforations in these metal sheets offer enhanced functionality. They enable controlled passage of air, light, and sound while providing necessary protection or separation, depending on the application. This characteristic makes them ideal for diverse applications across industries.Customization and Versatility

Perforated metal sheets can be customized in terms of hole size, pattern, and material, catering precisely to the requirements of specific projects or applications. This versatility allows for tailored solutions in design, functionality, and appearance.

Hole Shapes and Patterns

Manufacturers offer a wide array of hole shapes and patterns, including round, square, slotted, hexagonal, and custom designs. These options provide designers and engineers the freedom to select patterns that align with their aesthetic or functional needs.

Material and Thickness Variations

Perforated metal sheets are available in various materials such as stainless steel, aluminum, brass, and galvanized steel. Additionally, different thicknesses cater to specific strength or weight requirements, ensuring compatibility with diverse applications.